|

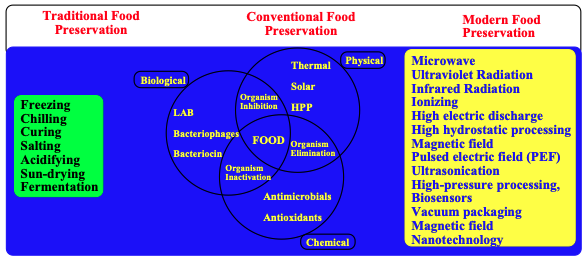

Introduction The ever-increasing global population, coupled with the increasing complexities associated with food safety and security, has placed serious pressure on available food resources [1,2]. The preservation of food has been a critical element of the food industry for a long time, as it is necessary to ensure the safety and quality of food products over a prolonged duration. While drying, salting, freezing, fermentation, smoking, and some others (Figure 1) have been the traditional methods of preservation for centuries, recent technological advancements and evolving consumer requirements have led to the emergence of novel and innovative food preservation techniques [3,4].

The food preservation industry has been transformed by new and innovative techniques, leading to improved efficiency and effectiveness. This is accomplished by the emergence of new preservation techniques generally categorized as chemical, biological, and physical methods. Since the preservation techniques have overlapping features, classifications have become complex. Chemical preservation techniques are particularly popular due to their ability to maintain the nutritional and sensory quality of food products for an extended period [3]. These methods are often combined with refrigeration and freezing to achieve optimal results [5,6]. New and advanced packaging techniques have been developed to further extend the shelf life of food products. One such technique is modified atmosphere packaging (MAP), a process that changes the atmospheric condition inside a package to slow down the deterioration process of food products. Another technique is active packaging, where active agents are added to the package to prevent microbial growth and oxidation [7]. The reduced oxygen and carbon dioxide content in the enclosure alters the metabolic process of microbial activities significantly and thereby extending the shelf-life of the packaged food [8,9]. These innovative packaging techniques have been proven to be effective in preserving a variety of food products, such as fruits, vegetables, meats, and dairy products. By using these techniques, the quality of the food products is maintained for a longer period, resulting in less food waste and increased available food products for consumers. Incorporating innovation into food preservation has significant implications for the food industry. In addition to extending the shelf life of food products, it has the potential to decrease food waste, enhance food safety, and augment the availability of food products. By preventing the spoilage of food products, more food can be supplied to regions that may lack access to fresh food, thereby improving food security and combating food scarcity [7]. Food preservation techniques have significantly brought about a variety of effective methods that have helped address challenges in the food industry. This review examines the impact of innovations on food preservation, with a focus on emerging techniques and their transformative impact on the food industry. The review provides a quick insight into some latest innovations in food preservation and their implications in the food industry.

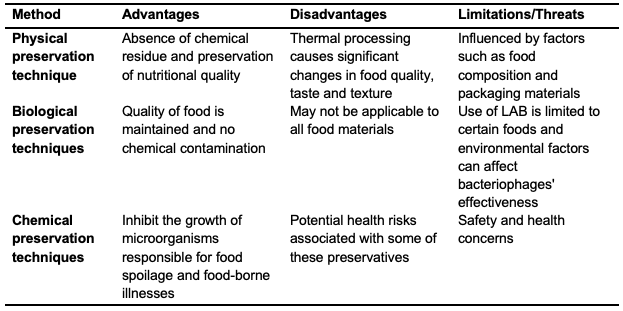

Preservation Techniques Chemical Preservation Method Chemical preservation techniques have significantly impacted the food industry by providing effective means to preserve food products for extended periods while maintaining their nutritional and sensory quality. Kalem et al. (2018) [3] submitted that chemical preservation techniques have gained tremendous popularity in the food industry due to their ability to preserve food products while maintaining their quality. The chemical preservatives used in food products are typically antimicrobial agents that inhibit the growth of microorganisms responsible for spoilage and food-borne illnesses [10,11]. Sodium benzoate is a chemical preservative commonly utilized against molds, yeasts, and specific bacteria [12]. Sulphur dioxide, on the other hand, has become a popular preservative in fruits and vegetables such as wine and dried fruits due to its antioxidant and antimicrobial effects [3]. Nitrites and nitrates are also frequently employed in meat preservation to prevent bacterial growth and preserve colour and flavour [3]. Other chemical preservatives that have been used to inhibit microbial growth in food include sorbate, hydrogen peroxide, parabens and benzoates. The use of chemical preservatives in food products has caused concerns among consumers and health experts due to potential health risks associated with some of these preservatives. Research has shown that some chemical preservatives, including sodium nitrate and nitrite, may increase the risk of certain cancers [12] besides having harmful implications on the freshness and sensory properties of certain food [13]. This has led to rising demand for natural and organic preservatives in the food industry as consumers increasingly seek healthier and safer food options. The use of chemical preservatives in food products has thus raised concerns about their safety and health effects. As such, there is a need for continued research and development of natural and organic preservatives to meet the changing needs and preferences of consumers. Apparently, the issues of consumers’ trust and acceptance of preservative method and technology cannot be overemphasized [14]. Recent surveys have indicated that most consumers, particularly those that prioritizes health over economic gain, prefer thermal preservation to others, including chemical means, for fear of incorporation of xenobiotics in the process [15].

Biological Preservations Techniques Biological preservation techniques have revolutionized the way food products are preserved, offering a more natural and safer alternative to chemical preservatives. These techniques involve the use of naturally occurring microorganisms or enzymes to prevent the growth of harmful bacteria and spoilage microorganisms in food products. Ktari et al. (2020) [16] noted that biological preservation techniques provide several advantages over chemical preservatives, including the ability to maintain the natural quality of food products and reduce the risk of chemical contamination [17]. One of the mostly adopted biological preservation techniques is the lactic acid bacteria (LAB) used to ferment and preserve food products such as meat, dairy, and vegetables. LAB produces lactic acid as a by-product of fermentation, which creates an environment that inhibits the growth of spoilage microorganisms by lowering the pH of the food product. This process not only preserves the food but also enhances its flavour and nutritional value. The use of LAB is effective in preserving a wide range of food products, including cheese, yogurt, sausages, and pickles, among others [16]. Another interesting biological preservation technique is the use of bacteriophages. Bacteriophages are a type of biological preservation technique that has been used in the food industry to control the growth of harmful bacteria responsible for foodborne illnesses, such as Salmonella sp. and Escherichia coli by infecting and killing specific bacteria [18]. Although these techniques offer several advantages over chemical preservatives, they also have limitations. For instance, the use of LAB may not be suitable for all food products, and bacteriophages' effectiveness may be affected by environmental factors such as temperature and pH [16]. Despite the advantages of biological preservation techniques over chemical preservatives, these methods suffer some setbacks with respect to environmental impact [19]. Specifically, the use of antilisterials as biocontrol of L. monocytogenes in foods have the demerit of intolerance in unfavorable environmental conditions. The low-stress accommodation potentials and the alteration of food taste are a major setback. Most importantly, the lysogenic phages could be vehicles for horizontal gene transfer and also, some bacteriocins may induce changes in the diversity of intestinal microbiota in different regions of the gastrointestinal tract [20]. As a result, additional research is required to enhance the effectiveness and suitability of these techniques for various food products and settings [6].

Physical Preservations Techniques Physical preservation techniques refer to the application of physical means to prevent food spoilage. These methods have been developed as alternatives to chemical and biological preservation techniques, mainly to overcome their limitations that affect food quality and safety. This technique is often preferred because it is devoid of the incorporation of chemical or biological agents into the food. The technique has been adopted in the preservation of milk and meat products among others [21]. High-pressure processing (HPP) is one of these physical preservation techniques, which entails exposing food products to high levels of pressure to inactivate microorganisms and enzymes that induce spoilage [22]. HPP is efficient in preserving the safety and quality of diverse food products like juices, meat, seafood, and fruits, while retaining their nutrient content and flavour [23-25]. Thermal processing is another physical preservation technique that involves using high temperatures to eliminate microorganisms and enzymes in food products [26]. This technique is commonly used in the canning industry to preserve food products such as fruits and vegetables for extended periods. Thermal processing can also be used to sterilize dairy products and milk, which are susceptible to bacterial contamination [27-31]. Although physical preservation techniques provide several benefits over chemical and biological techniques, such as the absence of chemical residue and the preservation of nutritional quality and flavour, they also have limitations. For example, some physical preservation techniques like thermal processing, which makes use of external heat, can cause significant changes in food quality, taste and texture [26]. Additionally, the effectiveness of physical preservation techniques may be influenced by various factors, such as food composition, processing conditions, and packaging materials [22]. Since food with fresh-like characteristics, a high nutrient content, and preserved sensory quality traits is consumers’ preference, these qualities are rarely maintained in sufficient ration when food is subjected to heat processing, as the heat treatments diminish sensory qualities such as flavor, color, and vitamins. The diminished qualities often warrant the inclusion of more supplements following the heat treatment [32,33]. Incredibly, thermal techniques of food preservation have received continuous modifications and improvement for optimum product preservation thereby delivering food products with better quality [34]. The advantages and disadvantages of the three conventional methods are discussed in Table 1.

Other Preservation Techniques The concept of food preservation has continued to receive attention as more innovations are being introduced. Some other modern innovative techniques being adopted in recent times include the use of microwave, ultraviolet, infrared, ionizing, high electric discharge, high hydrostatic processing, magnetic field, pulsed electric field, ultrasonication, nanotechnology and some others [35,36]. The low thermal conductivity of food makes conventional heating of food relatively slow. Microwave technology has been reported as a food processing technique which enables processing within a short period of time compared to conventional heating. Hot air-drying is usually employed by industries as the main dehydration technique. This method, however, presents several problems such as poor quality of the dried product. The rate of drying reduces with time and water removal becomes ineffective. Thus, severe conditions are required for conventional hot air drying, resulting in frequent overheating and over-drying of the food materials. These reasons led to the microwave heating method to be developed and proposed as a new drying technique for food preservation [22]. The ultrasound preservation technique has been presented as an innovative method for food preservation. It is employed in the food industry for a number of purposes such as food analysis and food processing (homogenization, freezing, degassing, cutting, drying, antifoaming and extraction). Some advantages of the ultrasound method as a food processing technique includes effective mixing, reduced temperature, reduced energy and increased production rate. The ultrasound method also enables the elimination of microorganisms without destruction of nutrients of foods in food preservation. In addition, low-power ultrasound is reported as an attractive and non-thermal technique which could be employed to avoid problems such as physical and chemical changes, nutrient loss and organoleptic property change [37]. The infrared radiating heating technique has been reported to be one of the best ways of reducing heating time for food processing. This method gives a significant advantage over conventional heating including the possibility of achieving uniform heating, less loss of quality, and the absence of solute migration in food materials. In addition, significant energy is saved by utilizing this method [38]. Nanotechnology is concerned about atoms, molecules, or macromolecules with size range of approximately 1–100 nm. The nanomaterials possess dimensions and internal structure which are within 1 to 100 nm scale, allowing the observation and material manipulation in the nanoscale region. The presence of bioactive components in functional foods makes the foods prone to degradation and eventually leads to inactivation when subjected to a hostile environment. Nano-encapsulation of these food materials can extend the shelf-life of food products. Degradation of the food materials is usually slowed down or prevented when encapsulated in nanostructures for delivery to target sites. New nano-antimicrobials have shown promising effects in safeguarding food from deterioration. Nano-based food packaging has major advantages over conventional packaging because it provides better materials with improved mechanical strength, barrier properties and anti-microbial films [39].

Impact of Food Processing Innovation The Impact of Food Processing Innovation on Food Safety The development and implementation of novel technologies and protocols in the food preservation sector has had a substantial impact on food safety and security. Foodborne illnesses are still a major worldwide health problem because they cause high rates of morbidity and mortality in addition to extensive economic loss [40]. Innovative technologies such as nanotechnology, biosensors, and blockchain have been found to improve food safety and quality [41]. The use of biosensors in food packaging can detect the presence of harmful microorganisms or pathogens in real time, enabling prompt intervention to prevent foodborne diseases. Similarly, nanotechnology can enhance the effectiveness of food processing and preservation while reducing the risk of contamination [42]. Blockchain technology has also boosted supply chain transparency and traceability, thereby enabling faster identification and recall of contaminated food products [43]. Furthermore, food innovation has sparked the development of innovative, safer, and more nutrient-dense food products. For example, it has been determined that plant-based ingredients used in meat substitutes are healthier than animal products, which lowers the risk of foodborne illnesses [44]. The development of probiotics and functional foods has also been identified as an effective way to enhance gut health and boost immunity, thereby reducing the risk of foodborne diseases. Innovations in the food industry have the potential to transform food safety by introducing new technologies, processes, and products that enhance the safety and quality of food products. Nonetheless, it is crucial to subject these innovations to rigorous testing and regulation to guarantee their safety and effectiveness. Compared to traditional heat processing processes, Pulsed Electric Field, for instance, is thought to be a highly energy-efficient and ecologically benign procedure. Ultraviolet radiation preservation methods are environmentally benign, safe for use on both solid and liquid foods, and effective in preventing recontamination when applied to pre-packaged food goods. Furthermore, it has a reduced processing time and excellent food penetration without posing a significant risk to customers' health [45].

The Impact of Food Processing Innovation in Reducing Food Waste Food innovation has been instrumental in reducing food waste through various means. New technologies, processes, and products have been developed to extend the shelf life of food products, reduce spoilage, and improve supply chain management [16]. By extending shelf life, active food packaging lowers food waste while protecting and preserving food content through processes brought on by intrinsic and acquired variables such as the incorporation of antioxidant and antimicrobial agents during packaging or as packaging materials [46]. Global estimates indicate that between 27% and 39% of the entire yearly harvest of fish is lost largely due to poor processing and preservation, thereby making fish waste a major global concern [47]. This underscores the imperativeness of innovative and smart food preservation. Modified atmosphere packaging (MAP) is an example of such innovation, which alters the air surrounding food products to prolong their shelf life [22]. MAP has been successfully used in preserving various types of food products, including meat, fish, fruits, and vegetables. Smart packaging technologies, such as time-temperature indicators, are also an innovative approach to reducing food waste by providing real-time information about the condition of the food product and preventing spoilage and waste [31]. Additionally, the development of apps and software that facilitate food donation and redistribution has assisted in connecting surplus food products with food-deficient areas thereby reducing waste [43]. Food waste is being adopted as a resource in new product formulations and processes that have been developed as a result of innovations in the food sector, which has decreased food waste. For instance, food waste can be turned into biofuels to reduce its negative environmental effects and offer a reliable supply of energy [22]. Similarly, food waste can be used as a raw material in the production of new food products, such as upcycled snacks and beverages, which can create new markets and reduce waste [16]. Food innovation has significantly reduced rapid degradation and waste through the development of innovative technologies, processes, and products that improve food preservation, supply chain management, and utilization of food waste as a resource. Nonetheless, it is necessary to continue research and development to enhance these innovations and tackle the global challenge of food waste.

Conclusion The use of innovative technology and methods to increase the quality, safety, and shelf-life of food products has revolutionized the food industry. Although conventional techniques of chemical, biological and physical methods of preservation have been used to achieve a longer shelf-life of food, chemical preservation techniques seem to be more widely used partly due to their availability, affordability and tendency to maintain the nutritional quality of food products for prolonged periods. These innovations, such as high-pressure processing, thermal processing, biosensors, and nanotechnology, have resulted in improved food safety and decreased food waste. Nevertheless, it is necessary to carry out further research and development to confirm the safety and efficiency of these technologies. Biosensors, thermal processing, high-pressure processing, nanotechnology, and other advances have led to reduced food waste and increased food safety. However, further study and improvement are required to verify the efficacy and safety of these technologies. Globally, food innovation has changed consumers’ perceptions about food preservation, and with more improvement, it may be able to solve pressing problems with sustainability and food safety. The Sustainable Development Goals (SDGs), especially SDG 2, which aims at ending hunger while minimizing food loss and negative environmental impacts, can be fulfilled in part by using the emerging cutting-edge, novel food preservation techniques. It is also emphasized that the adoption of new food preservation innovations, customer preference and safety must be prioritized. To ensure that customer expectations and demands are met in an efficient and useful way, the application of innovation must be periodically evaluated together with safety throughout the processing and preservation stages.

References

|

||||||||||||||||||||||